October 26, 2017

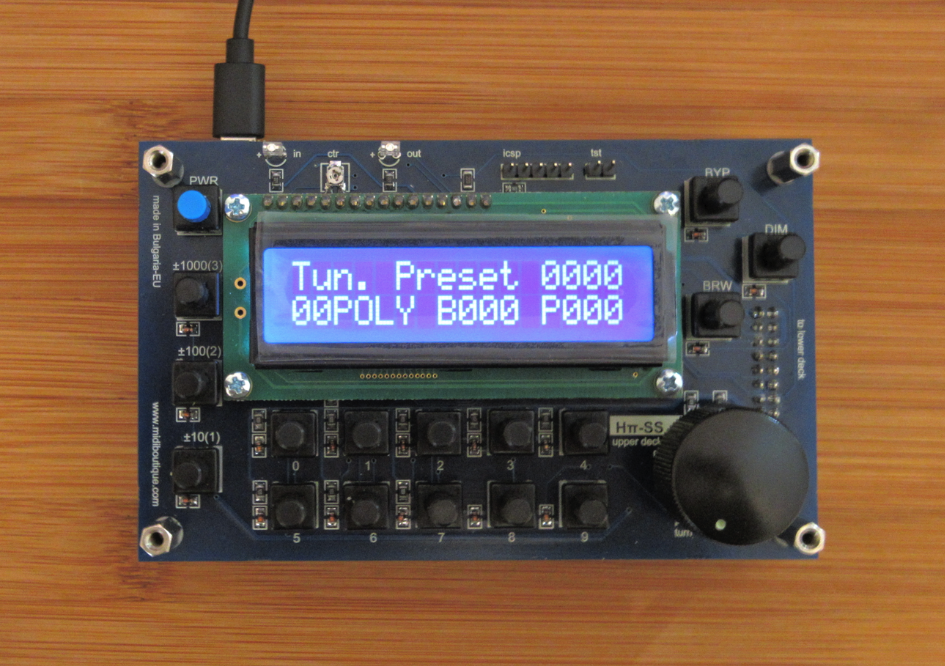

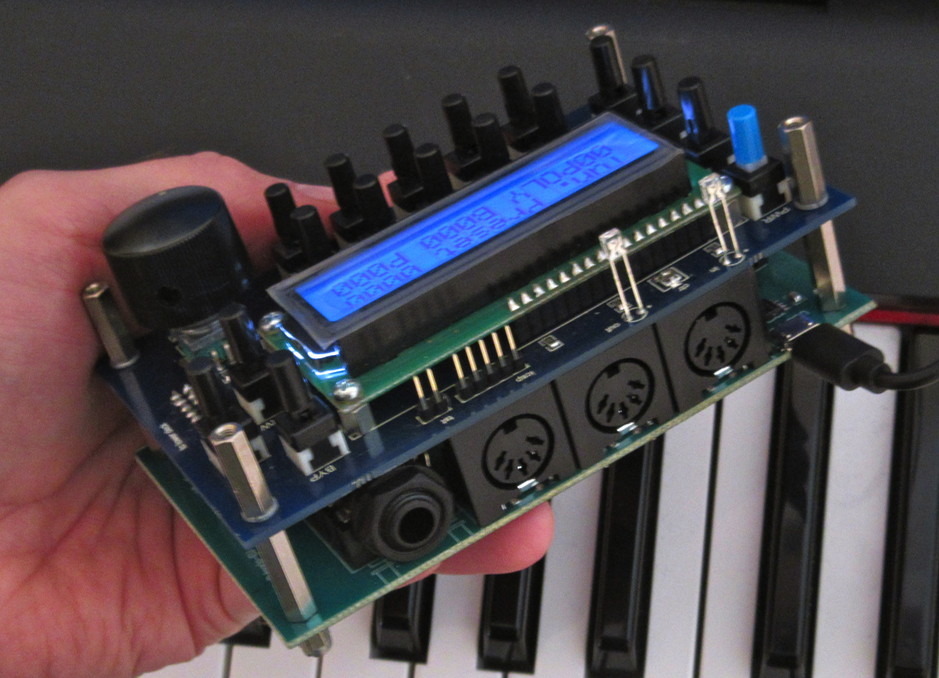

For the past couple of months, I've been testing the first prototype TBX2 Scale Station. In fact, this is the second prototype revision, the first having been made with a different microcontroller which turned out to be too limiting. I wrote previously a bit about the stacked PCB design. Here is what the device looks like without an enclosure.

In addition to functional testing, my job has been to turn this prototype into a finished product. That involves not only working with Jordan to finish the firmware and writing software for managing scale data on a desktop computer, but also designing and building a proper enclosure.

It may be tempting to think that this device could be used without an enclosure, but that wouldn't be wise. An enclosure serves a dual purpose: to complete the user interface and the final appearance, and (more importantly) to secure and ground electrical connections and shield and protect the circuit boards and components. The enclosure makes the unit robust, portable, reliable, and much more user friendly.

My previous enclosures used thin sheet aluminium covered with printed adhesive vinyl and protected with a UV coating. TBX1 had such an enclosure, with plastic side pieces. These enclosures looked nice enough, but were easily damaged, both cosmetically and structurally. The overall impression was good, but a little less than solid. These enclosures also took a long time to make. UV coating requires aerosols. After ten years of environmentally dubious spraying, I decided to avoid doing that in the future.

The enclosure I've designed for TBX2 is stronger and simpler than my previous ideas. It's a box made of two pieces of aluminium and two pieces of bamboo. The button holes and interface openings, display, and I/O, are all done by hand.

I considered several different possibile methods for adding labels for the buttons and ports, including decals, screen printing, and toner transfer — methods which are finicky and require spray coverings. Ultimately I decided to avoid all superficial coverings, and work the interface design into the metal itself by stamping. I found that when elements are stamped directly into the metal, the device looks and feels more solid. You may also notice in the images below that I cut a second set of bamboo sides just a bit smaller than the first try, keeping the corners a bit more square.

Metal stamping is not for the faint of heart. It's not easy to do it well, and it requires a lot of tools, which aren't cheap, such as the stamps themselves, stamping block, and brass hammers. Individually hand stamping every marking on an enclosure would be very time consuming, so I designed a unique stamping table which secures the workpiece and features a system of wooden jigs to hold many stamps in place at once, so that I can prepare an enclosure much more rapidly. The impressions from the stamps are filled with a fast-drying ink, and the excess is sanded away from the surface, giving the metal a smooth burnished look. Note that these pictures are of the first prototype enclosure which is not perfect. The markings are also likely to change slightly on the finished product.

Of course, an enclosure does take some time to make. This has always been the case with my designs, which rely on what might be called my own primitive manual labour. I feel the result is worth it. When I use my time to build something creative like this, I don't feel like I'm working. To me it's kind of like art. I enjoy it.

The big news is that more than enough interest has been shown in the device to merit making 100 of them. I've set up a product page, where from now until the end of November, you can reserve a unit with a payment of 40 €. This gives you a 60 € discount on the pre-order which is planned to take place during the month of December. The regular cost of the unit is not yet firmly decided, but it is currently estimated at 359 €. In addition to the earlybird discount, there may also be time-dependant percentage discounts during pre-order, so that the sooner you buy the more money you can save. It's sort of impossible to know in advance, but according to all the emails I've received from interested buyers, it seems likely that the units may sell out quickly. So again, I suggest reserving a unit now, and if you have any questions, just send an email. Documentation is available online, as the Updated TBX2 Public Specification. Note that this resembles our internal specification more than a normal user manual would. The information will be reworked and updated into a friendlier user manual later. You might also want to check out the previous information I've shared about the unit on the blog here and here. Thanks as always for your support!

Best Regards,

Aaron

[ Showing 1 entry | Previous entry | Next entry | Show all entries ]